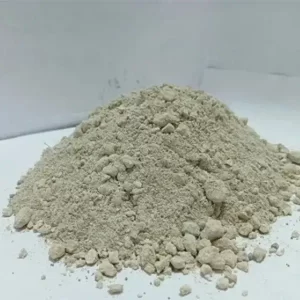

Casting Powder Introduction:

Casting powder, also known as casting flux, is a finely powdered material used in metal casting processes to improve the quality of the casting and facilitate the casting operation. It plays a crucial role in both investment casting (also known as lost-wax casting) and sand casting, which are common methods for creating intricate metal parts and sculptures. In investment casting, casting powder is used to create a barrier between the wax pattern and the ceramic mold during the shell building process. This prevents the wax from sticking to the mold and allows for smooth removal of the wax during the dewaxing stage. Continuous casting refractory materials are in great demand these days as more and more iron and steel making companies around the world are today opting for continuous casting of steel.

Casting Powder Application:

Casting Powders are imperative materials amid uniform steel casting procedure. These permit the production of lubricating films over mold surface as well as avert solidification of metal to stick to the mold. It implies that the liquidified metal can freeze easily and fast sans any contaminants adhering to the powders. These are majorly utilized in metal, construction and many more industries. They are acid refractories that are accessible in metal powder forms for distinctive applications. Our Casting Powders have adjusted composition, precise pH levels, longevity and lifted performance under varied working environments. These also include Mgo, Cr2O3, Al2O3 and many more compounds.

Casting Powder Advantages:

Casting Powder contains low melting constituents that instantly generate liquid slag, which penetrates into the gap between the mould and the solidifying shell of the billet. Casting Powder is added in small amounts and continuously over the casting duration. The melting of the Casting Powder occurs slowly in layers. Hence, the top surface of the liquid metal in the billet / slab / bloom always remains protected from the atmosphere.

- Consistency and Reproducibility

- Easier Cleaning and Maintenance

- Reduced Metal Loss

- Controlled Solidification

- Reduced Air Entrapment

- Improved Heat Transfer

The choice of a Casting mould powder depends on:

- Mould size

- Oscillation conditions

- Casting speed

- Steel grade

Reviews

There are no reviews yet.