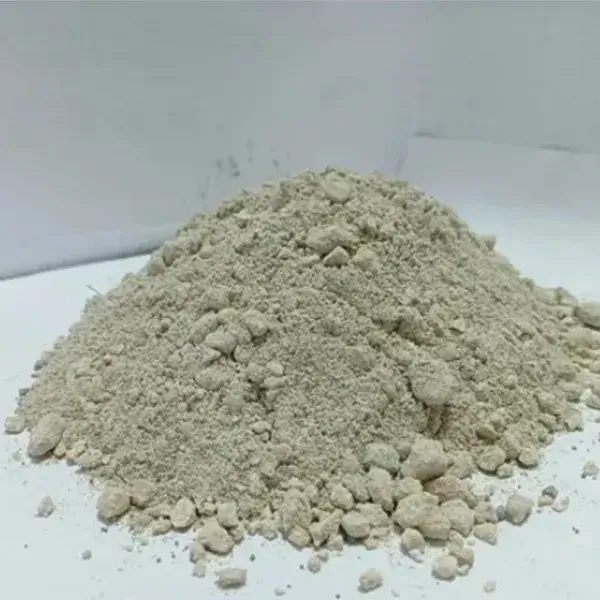

Tundish coating material is composed of magnesia and magnesia-calcium materials with binding agents and admixtures, and is characterized by good corrosion resistance, easy application and easy removal. The maximum use temperature is 1750℃, and the steel receiving time is more than 8 hours, the use effect is better.

The tundish linings with basilite coatings are easy to install and have end-to-end safety assurance. Our tundish refractory linings for induction furnaces minimise risks of hydrogen pick-ups, and ensure that there is very little (if any) temperature loss. Made from industry-standard raw material, these linings offer extended service lives, ruling out system downtime risks. By implementing the latest technology in our tundish lining solutions, we ensure optimal energy-efficiency and excellent slag resistance.

Benefits of Tundish Coating:

- Improved safety

- Simplified installation

- Extended service life

Tundish Coating Application:

Generally speaking, the higher the CaO content is, the better the cleaning effect of tundish coating material will be. But there is no definite value of CaO content, and the high CaO content coating material is hard to produce. The service life of magnesia calica tundish coating material is correlated with the thickness of the coating layer. Generally speaking, the continuous casting times is between 8 and 10 if the coating thickness is 35~40mm, while the continuous casting times is over 10 if the coating thickness is 40~60mm.