1.Refractory materials for tundish

The refractory components of the tundish include the ladle body, ladle cover, upper and lower nozzles, stopper rods, slag weirs and dams, flow stabilizers, and impact plates. The refractory brick-built tundish is divided into lining refractory materials (working layer, thermal insulation layer, and insulation layer), continuous casting refractory materials, and precast refractory materials. Due to the location and usage requirements of the tundish, the physical and chemical properties and performance of the refractory materials used vary. High-quality refractory materials are a prerequisite for ensuring the service life of the continuous casting tundish. We can provide a variety of tundish refractory materials according to your requirements. Zircon bricks or precast blocks are used in the steel injection area at the bottom of the ladle.

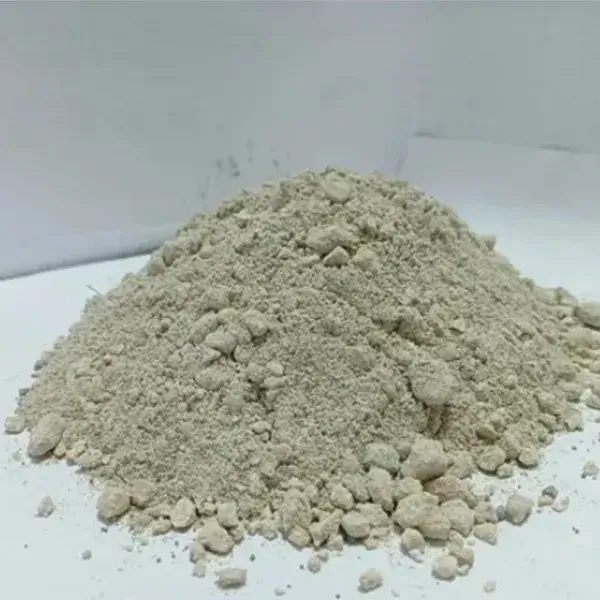

The tundish lining mainly consists of an insulation layer, a fixed layer, and a working lining. The insulation layer is made of clay bricks or insulation boards, and is generally made of low-cement or ultra-low-cement castables with a content of 60% to 80% alumina. The working lining must meet the following conditions:

(1) It is resistant to corrosion by molten steel and slag and has a long service life;

(2) It has good thermal shock resistance and will not burst when in contact with molten steel;

(3) It has a low thermal conductivity and thermal expansion coefficient, and the tundish lining has certain thermal insulation performance and good integrity;

(4) It will not contaminate the molten steel during pouring;

(5) It is easy to assemble and disassemble.

2.Continuous Casting Tundish Refractory Construction Technology

With the development of refractory materials, the main construction techniques for tundishes include composite refractory brick masonry and bulk casting of bulk materials. The saying “30% material, 70% construction” illustrates the importance of construction. Various construction techniques meet the diverse needs of users. For continuous casting tundishes, we recommend using a bulk casting process to improve the tundish’s sealing and extend its service life. The thickness of the refractory layer for medium and small tundishes is generally around 100-120mm, while that for large tundishes is around 150-200mm.

The use of refractory slag walls in the working layer of the steelmaking tundish is crucial.

Refractory materials for slag weirs in smelting tundishes: the materials, physical and chemical properties, and disadvantages of the flush plates and weirs, as well as the impact of molten steel flow rate on the tundish.

Theoretical residence time is calculated as the time between the residence time of molten steel in the tundish and the total steel flow rate. However, molten steel flow within the tundish is uneven, with some areas experiencing faster flow and others experiencing slower flow. In particular, the bottom of the tundish contains stagnant areas of inactive steel, making it difficult for inclusions to float. Compared to theoretical calculations, the actual residence time of molten steel in the tundish is shorter. To fully and effectively utilize the tundish volume and promote the floating of inclusions, retaining walls and dams have been added to the tundish. The objectives are:

- Eliminate the dead zone at the bottom of the tundish;

- Improve the flow trajectory of the molten steel, allowing for interfacial flow between the steel and slag, shortening the distance over which inclusions float, and facilitating slag absorption;

- Confine the strong vortex generated by the ladle’s inrush flow to a local area, preventing turbulent diffusion from generating surface waves that could draw slag into the molten steel.

3.What issues should be paid attention to in the tundish drying furnace?

The tundish baking process generally requires a quick bake to 1000-1100°C one to two hours before pouring. This saves energy and facilitates operation. However, due to production scheduling and other factors, baking times are often extended, leading to potential safety hazards.

During the slab continuous casting process, the tundish is equipped with an integral aluminum-carbon stopper or an integral aluminum-carbon immersion nozzle. Prolonged baking times reduce product strength. If the surface anti-oxidation coating is poorly applied, the product will also oxidize and loosen, further reducing its strength and service life. Previous experience shows that when immersing the tundish, ensuring surface oxidation before wall thickness increases is crucial for extending its service life.

The strength profile is as follows: product strength decreases with increasing baking temperature, reaching a relatively low level between 500-600°C. As the temperature continues to rise, product strength increases until, at around 1300°C, the strength gradually decreases. Therefore, rapid baking is necessary to reach the desired temperature.

Because quartz immersion nozzles are baked at high temperatures for extended periods, the nozzle area can be left unbaked or baked at a lower temperature. However, long-term baking at high temperatures can cause crystallization, reducing the thermal stability of the product and even leading to cracks in the nozzle wall. This can lead to perforation and cracking during casting (of course, this is also related to the nozzle’s inherent quality).

Billet continuous casting tundishes are often lined with insulation boards and are not baked. Some steel mills only bake them at low temperatures, which only serves to dry the tundish. Billet continuous casting tundishes typically have three to six micropores with diameters of three to six. These nozzles should be thoroughly baked separately; otherwise, they may explode during use. Zirconium products have particularly poor thermal stability and can crack if not preheated properly.